CAD Story – A balance of technology and hand making

In combination with traditional hand-making skills, I use 3D CAD (Computer Aided Design) extensively in my work. I use it as a sketching and modelling tool to develop my jewellery designs – both for my collections and for bespoke projects.

In this blog post I shine a light on my use of CAD to develop new ideas and sculptural jewellery forms.

Modern engagement ring, 18ct gold with client’s own heirloom diamond

Acrobat Egg ring, 18ct yellow gold, 100% recycled

What is CAD?

CAD stands for Computer Aided Design. Although this technology has been around for a while its use in jewellery design is fairly recent. It enables designers to draw curves, surfaces, and solids in three dimensions on the computer. I use 3D design packages such as Rhino and Matrix.

The process of using these software tools and using 3D printing to create a wax model is called Rapid Prototyping. This versatile technique is now used in a wide range of manufacturing processes, from jewellery and furniture, to cars and aerospace.

Rapid prototyping and jewellery – how is it made?

Once the drawing is complete, I use the software to create a mesh of the model, this is then exported as a stereolithography file. This is a file that can be printed in wax.

The printer prints in two types of wax, model and supporting wax. It drops tiny droplets onto the bed of the printer, then cuts them back to a very thin layer, adds more droplets, cuts back and goes onto to build a block of printed wax. This block is then put into a solution that dissolves the supporting wax and it leaves the model wax, ready for casting.

The casting is done using the lost wax casting process. The wax models are attached to a cone of wax. This is then put into a cylinder filled with investment plaster, and the whole thing goes into a vacuum process, with molten metal on one side and suction of the other. As the molten gold or silver is drawn through the cylinder the wax melts away, the plaster holding in place. The plaster is then removed and you are left with the precious metal casting.

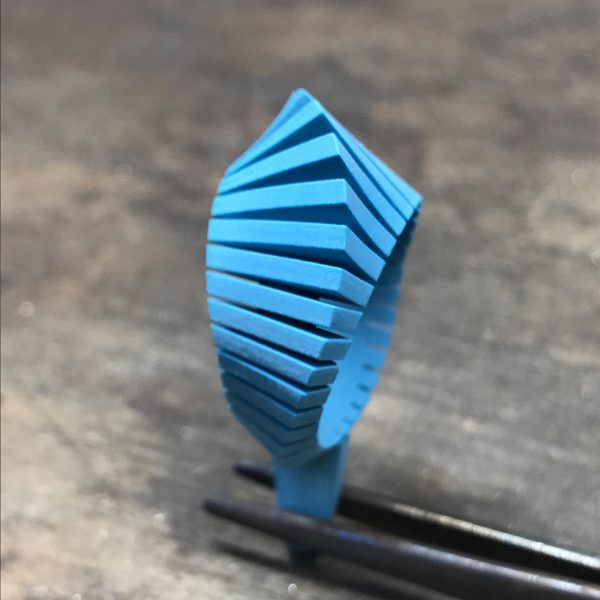

Here is an example of a ring design that is perfect for CAD 3D Design and the rapid prototyping process. The Fine twist egg ring won the Fine Jewellery Award from the Goldsmiths Craftsmanship & Design Council the year I first designed it.

- CAD design view

- Fine Twist Egg ring, 18ct yellow gold

How I use CAD for creative jewellery design

Having worked until 2005 as a commercial computer software designer, designing on the computer comes naturally to me. This technique gives me a freedom of design, generating unique sculptural shapes that woud generally not be possible to create by hand.

I tend to play around a lot with CAD when I am thinking of ideas. I use it as a means to sketch things out. It helps me to visualise things – to me it is like working with modelling clay but virtually.

This approach has allowed me to develop a very individual and cohesive style, attracting high praise and awards for the architectural quality of my designs.

Using CAD has opened up a world of possibilities in design. Years of experience at the bench gives me the understanding and ability to make the best use of the technology. In order to use these technologies successfully one needs to have a full understanding of hand making skills.

New developements in digital manufacturing

Additionally to Rapid Prototyping for jewellery we now have Additive Manufacturing which is an exciting new process. It enables printing from a drawing directly into precious metals. This really opens up what can be achieved – for example you could change metals and stop to insert stones during the printing process. You could also print fully articulated pieces. The possiblities are endless…

Design process for my Dune ring

The Dune ring is a new design inspired by the forms of sand dunes. I’m a fan of photographer Lee Miller and her style is always an inspiration – her desert photos are outstanding, as are Wilfred Thesiger’s photographs from his travels in the Rub Al Khali or Empty Quarter in the Arabian peninsula.

Lee Miller, Self Portrait, modelling Jean Patou, Paris, France, 1930

Photograph by explorer and writer Wilfred Thesiger

I start with hand drawn sketches to first develop an idea I have had in my head…

I will then move to the computer, as this is not a design that can be achieved successfully and within a reasonable budget with hand making. In the picture here you can see a Rhino screen – to create a drawing I will work in 4 views, top, front, side and perspective (this is the view where you can rotate the image about.)

When the CAD drawing is complete, I will print in wax, as shown below:

This is a wax that is ready for casting. Here is the end result, straight from the casting flask, ready to be finshed and polished by hand in the studio.

The Dune ring now comes in a few variations, some with a smooth finish, while others have modern ridges. It’s one of the advantages of working with CAD – I can develop and tweak designs for individual projects. Here are some examples of variations on the ‘Dune’ theme:

CAD as a tool for bespoke design

I also use CAD for bespoke projects – it is an incredibly useful tool for conveying design ideas to a client.

When designing for a client I would draw the item using CAD. I can then give the client a really clear 3D idea of what the piece will look like. I can change elements, colours and sizes of stones, try out different settings or gemstone sizes on an engagement ring for example.

Once my client is happy with the design, I will with either make by hand, or carry on and use the drawing to print a wax model ready to cast into precious metals. In general, I would only use CAD when it is not appropriate to hand make.

Bespoke Crane ring in platinum, set with a Paraiba tourmaline

Are you inspired to commission your own unique CAD designed piece?

Discover some recent commissioned pieces here or get in touch to start a conversation.